Mobile:+86-17717520739

Wechat:17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-11-02

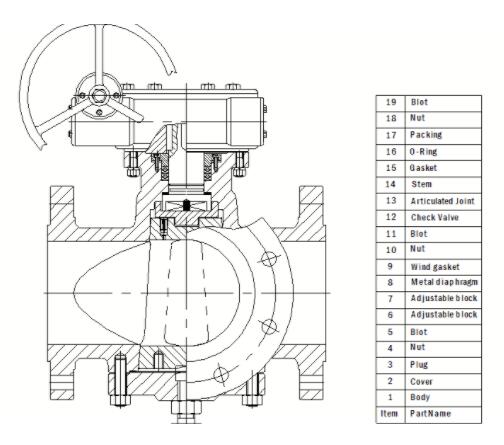

By lubrication, the movement of the plug and the space between the plug and the body get sealed. Lubricant is poured into a fitting at the top of the stem, which flows down the passage, through the plug top to the grooves on the plug, and down to a well that is below the plug. This pressurised lubricant passage is fitted with a check valve to keep the lubricant under pressure & to prevent backflow when more pressure is exerted at the time of operation.

Lubricated Plug valve consists of all the parts that are present in a conventional plug valve.

Due to taper locking, all valves are safeguarded against the potential of seizure. Taper locking is induced by a force imbalance exerted on the plug as a result of line pressure entering the bottom portion of the plug chamber. The resultant force tends to drive the plug higher, locking it in its tapered bore. The plug continues to remain in a locked position even when line pressure is lowered later on.

Traditional valves use the pressure of the plug sealant operating on the upper face of the plug to respond against the upwards force in an attempt to prevent taper locking. This lessens, but does not eliminate, the risk of taper locking, and therefore needs regular sealant injection to keep the valves free.

Lubricated Plug valve can be divided into two different types based on plug balancing.

The advantage of a dynamic pressure balancing lubricated Plug valve is that it guarantees that the pressure between the plug and the upper and lower body chambers is balanced. The two holes in the plug that link the plug ports to the upper and lower chambers balance the pressure. A check valve is installed in the top end hole to ensure that the pressure in the smaller chamber is always equal to or higher than the line pressure in the bigger chamber.

Lubricated Plug valve has a strong structure and are easy for in-line maintenance. Lubricated Plug valve is employed in situations where there are pulsing or static high pressures. Lubricated Plug valve can withstand pressures of over 2500 pounds per square inch. Lubricated Plug valve is ideal for media utilised in a variety of sectors, including petroleum, chemical, pharmaceutical, chemical fertiliser, and electric power. Lubricated plug valve are is prone to seizing or wear, and in some operating situations, they may have a slight increase in corrosion resistance